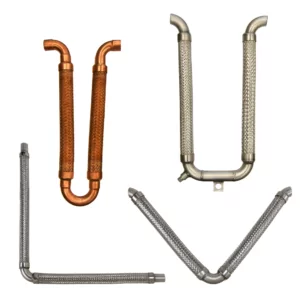

Bellows Type Pump Connector

Description

Maximum vibration absorption, Longest cycle life, Soft spring rate, Ease of installation and maximum safety.

Keflex™ Bellows-Type Pump Connectors are designed to compensate for multi-plane axial, lateral and angular movement in non-torsional applications. They are intended for use in both suction and pressure lines to absorb mechanical vibrations caused by pumps, compressors and other pipeline equipment. Bellows-Type Pump Connectors aid in compensating for minor piping misalignment and helping to minimize the stress on your system.

Heavy-duty restraining rods and spacers assure protection against bellows distortion in the event anchors are not properly secured. Keflex™ shatter-proof spacers absorb mechanical vibration without hampering axial, lateral or angular movement of the pump connector.

Multi-ply bellows were pioneered by Keflex™. Our standard product has a minimum of four (4) plies, but the larger diameter models are constructed with up to sixteen (16) plies. Most of the bellows-type pump connectors provided by competitors are produced “offshore” with only one (1) or two (2) plies.

Unlike rubber and elastomeric connectors, multi-ply laminated stainless steel bellows capsules are not subject to premature deterioration resulting from elevated temperature conditions or UV exposure. Thus, they offer a longer cycle life in a wide variety of temperature applications ranging from sub-zero to super-heated steam. In the latter case, it may be necessary to include the optional internal liner to prevent excessive flow velocity from damaging the assembly. (Available on welded-flange units only)

Standard units are designed for a total axial traverse of 5/8” (1/2” compression, 1/8” extension), a total lateral movement of 1/8” (1/16” each side of centerline), and an angular offset of 3-1/2 degrees maximum. Custom-built assemblies are available to meet conditions beyond these specifications.

Flanged-type series 150, 151 and 301-1215 assemblies from 2” to 12” ID measure a compact 5.0” face-to-face to save valuable space. Sizes of 14” ID and up measure 9.0” face-to-face. Custom lengths are always available. Welded flange-types 1512 and 3012 are 6” face-to-face OAL for sizes up to and including 8”. They are intended as replacements for short-style braided metal hose, rubber and elastomeric spool type expansion joints. For sizes 10” and larger, the standard OAL is 8” face-to-face. Lengths other than standard are available upon request.

Features & Benefits

Features:

- Up to 16 Stainless Steel Plies Soft Spring Rate

- 150# or 300# Drilling patterns

- Floating (Van Stone) flanges (Optional)

- Available in Multiple ID Differentials

- Elongated Bolt Holes

- Carbon Steel Tie Rods

- Chatter-Proof Spacers

Benefits:

- Max vibration absorption, safety, and cycle life

- Meets most installation needs

- No Concentric Reducer Required

- Ease of Alignment

- Prevents Over-Elongation

- Prevents Over-Compression

Submittals

Multi-Ply Stainless Steel Bellows-Type Pump Connectors

150-2115 Series

![]() Carbon Steel 150# Van Stone Flange Ends

Carbon Steel 150# Van Stone Flange Ends

![]() Carbon Steel 150# Van Stone Flange Ends w/Tie Rods

Carbon Steel 150# Van Stone Flange Ends w/Tie Rods

151-1215 Series

![]() Carbon Steel 150# Ends w/Tie Rods

Carbon Steel 150# Ends w/Tie Rods

152-TR-1215 Series

![]() Carbon Steel 150# Flange Ends w/Tie Rods

Carbon Steel 150# Flange Ends w/Tie Rods

1512-1215 Series

![]() Carbon Steel 150# Flange Ends w/Tie Rods

Carbon Steel 150# Flange Ends w/Tie Rods

301-1230 Series

![]() Carbon Steel 300# Flange Ends w/Tie Rods

Carbon Steel 300# Flange Ends w/Tie Rods

![hph[1]](https://www.kelcoind.com/wp-content/uploads/hph1-300x300.png.webp)